Features

- Increased pumping speed

Compared to ion pump, the cost (including cost of control equipment) per pumping speed 1L/s is approximately 1/2 to 1/3.

- Light weight and compact

Compared to ion pump with the same pumping speed, the volume and weight are reduced to 1/5 to 1/10. Therefore, it can be easily attached/removed to/from the pumped system to achieve high pumping speed with minimum space.

Applications

Deposition apparatus, electron microscopes, mass spectrometers, vacuum furnaces, various analysis equipment, experimental equipment, pumping equipment and other ultra-high vacuum systems with large gas discharge.

Specifications

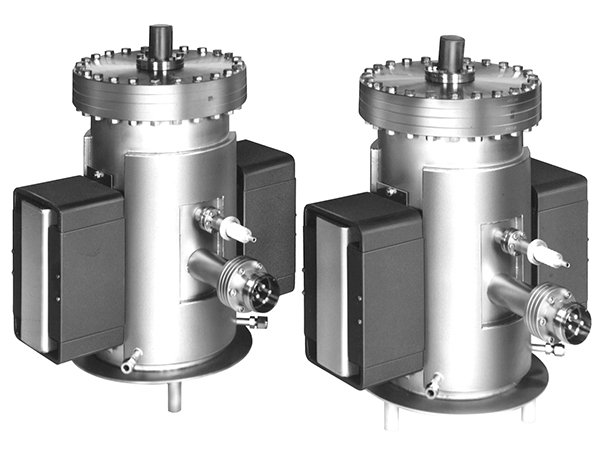

400L/s Combination Pump

| Pumping rate/Pumping flow |

See Fig. 1 |

| Operating pressure range |

10-1Pa to 10-9Pa |

| Baking temperature |

MAX250℃ |

| Weight |

Approx. 15kg |

| Intake flange |

φ152ICF flange |

| Approximate capacity |

4.5L |

| Applicable controller |

922-9119 Sublimation Pump Controller and PIC-052NP 20/60L/s Noble Pump Controller |

800L/s Combination Pump

| Pumping rate/Pumping flow |

See Fig. 2 |

| Operating pressure range |

10-1Pa to 10-9Pa |

| Baking temperature |

MAX 250℃ |

| Weight |

Approx. 25kg |

| Intake flange |

φ203ICF flange |

| Approximate capacity |

Approx. 7.5L |

| Applicable controller |

922-9119 Sublimation Pump Controller and PIC-052NP 20/60L/s Noble Pump Controller |

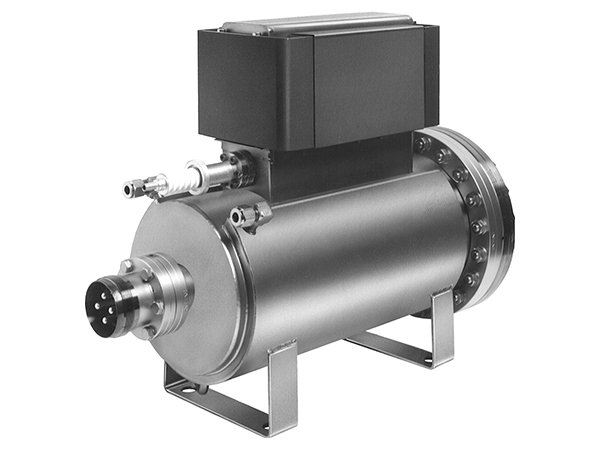

1600L/s Combination Pump

| Pumping rate/Pumping flow |

See Fig. 3 |

| Operating pressure range |

10-1Pa to 10-9Pa |

| Baking temperature |

MAX 250℃ |

| Weight |

Approx. 35kg |

| Intake flange |

Inlet flange φ253ICF flange |

| Approximate capacity |

Approx. 15.5L |

| Applicable controller |

922-9119 Sublimation Pump Controller and PIC-052NP 20/60L/s Noble Pump Controller |